ComfortCarry™

-

2021

-

Product

Domestic Appliances

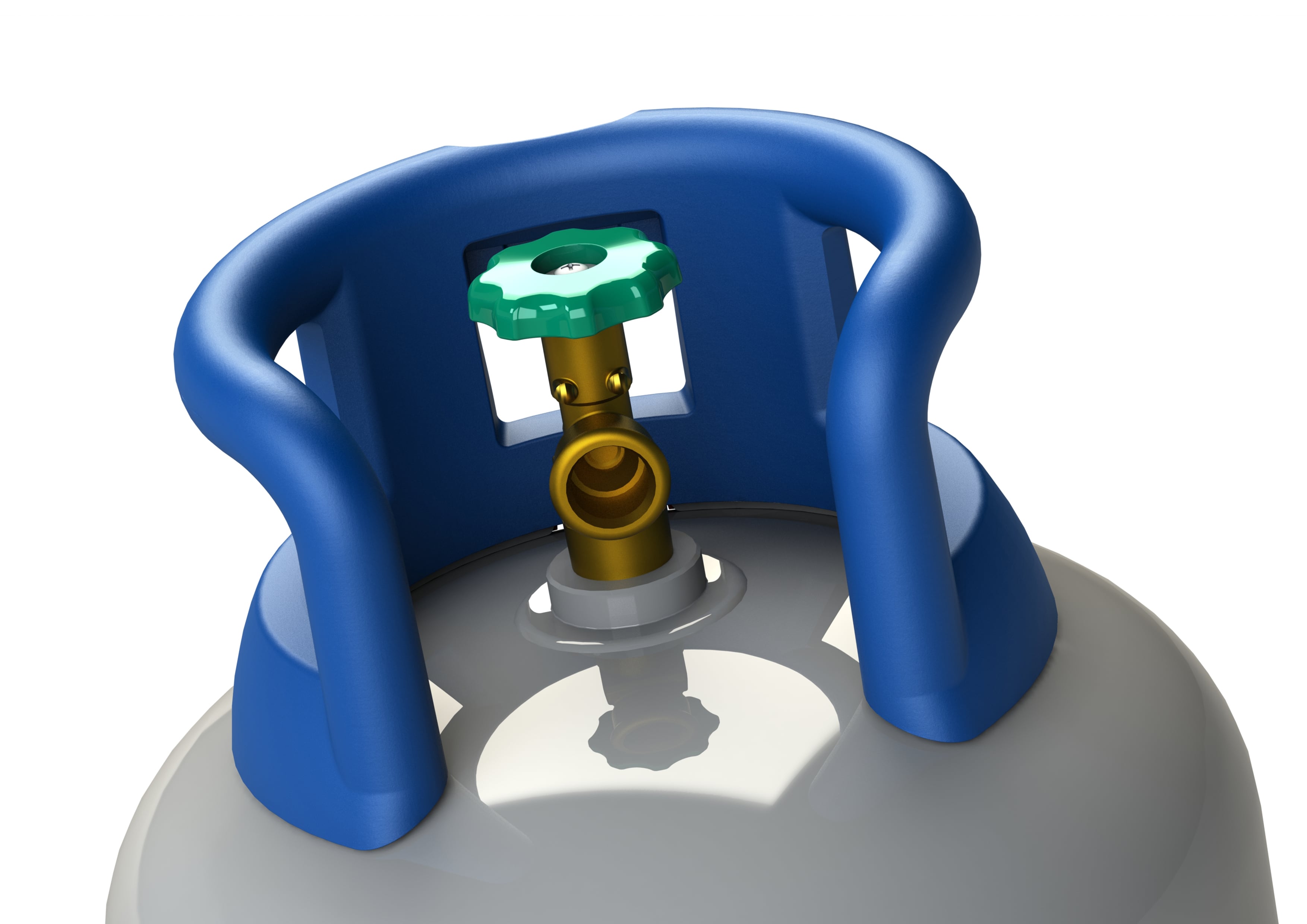

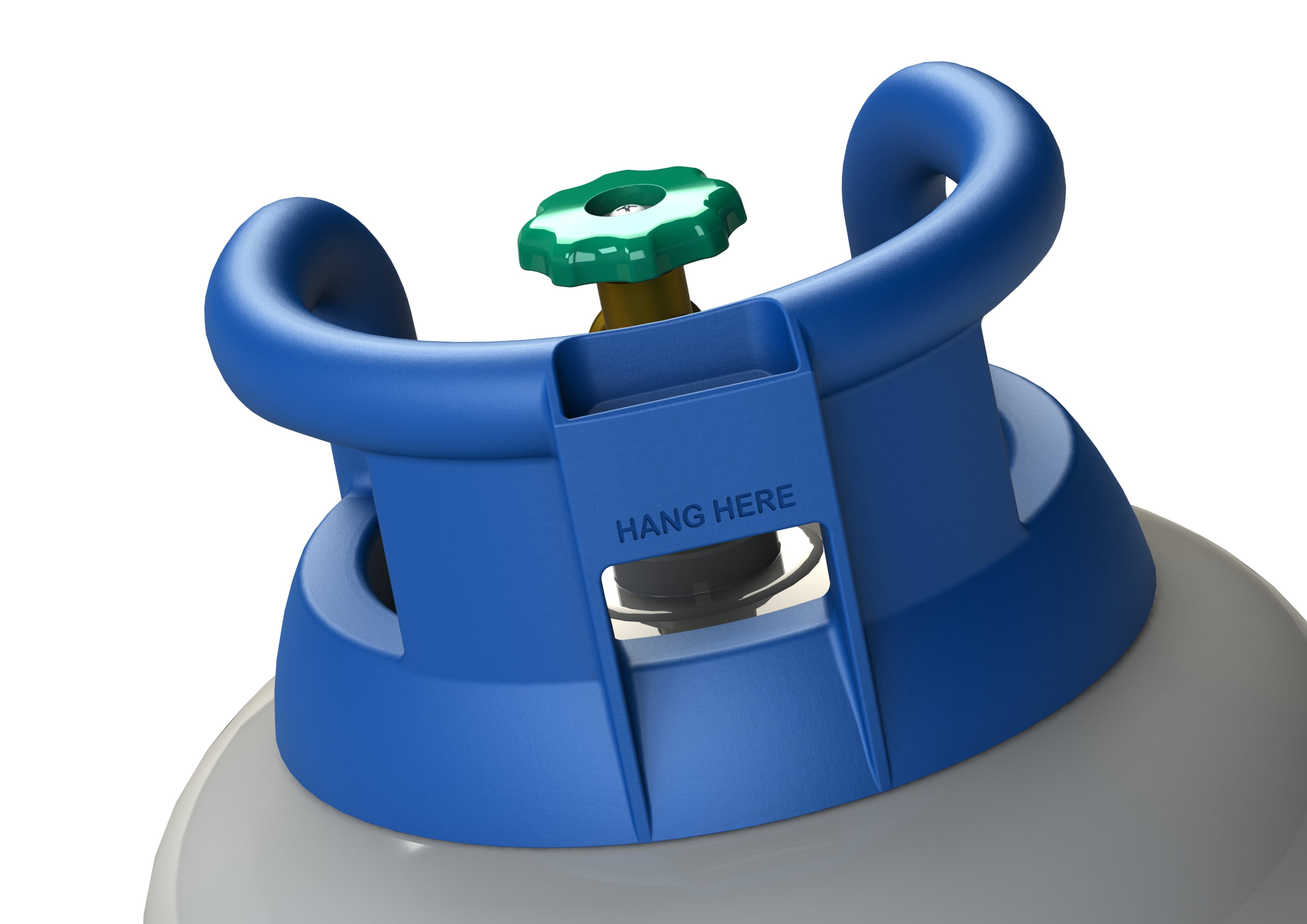

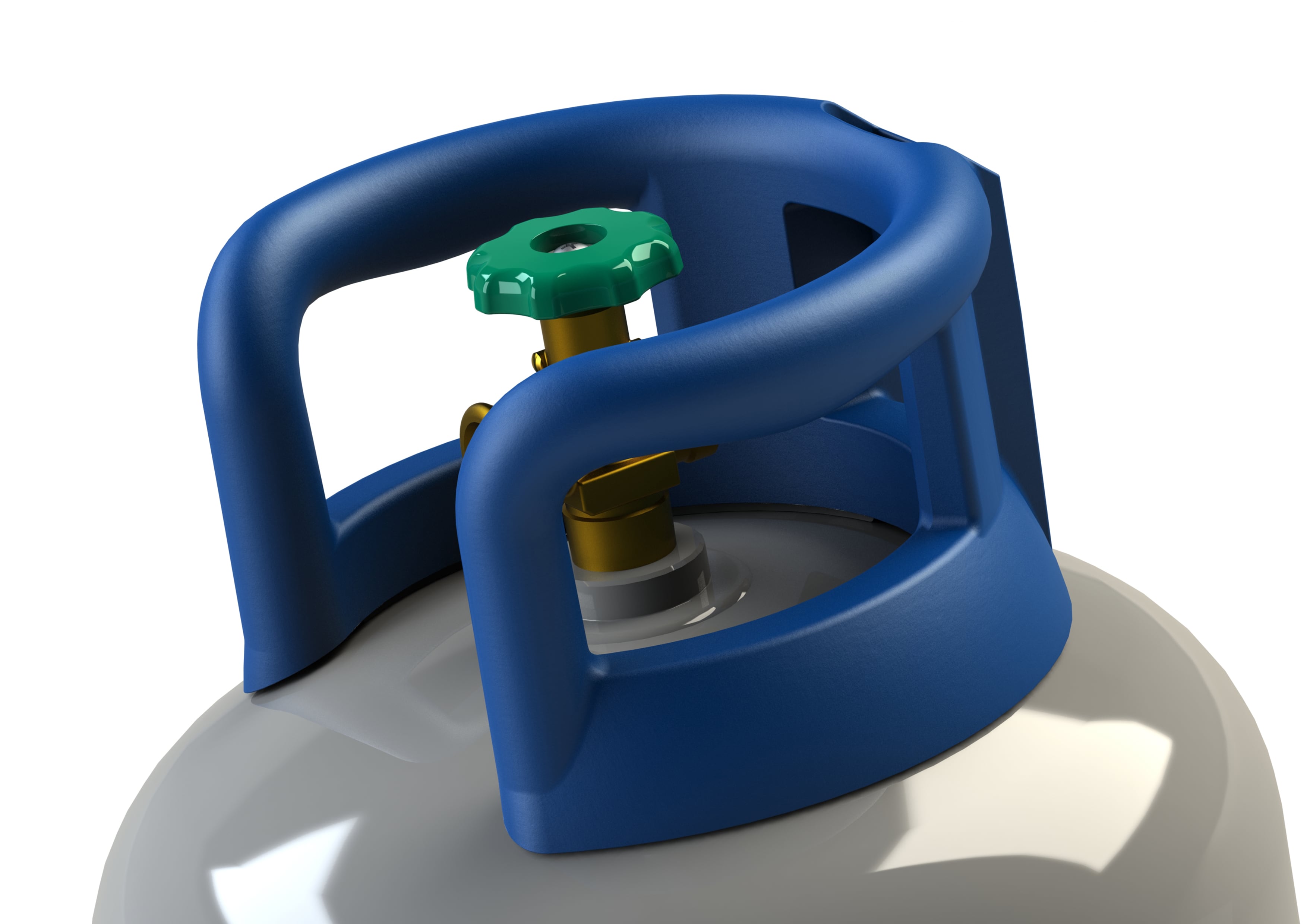

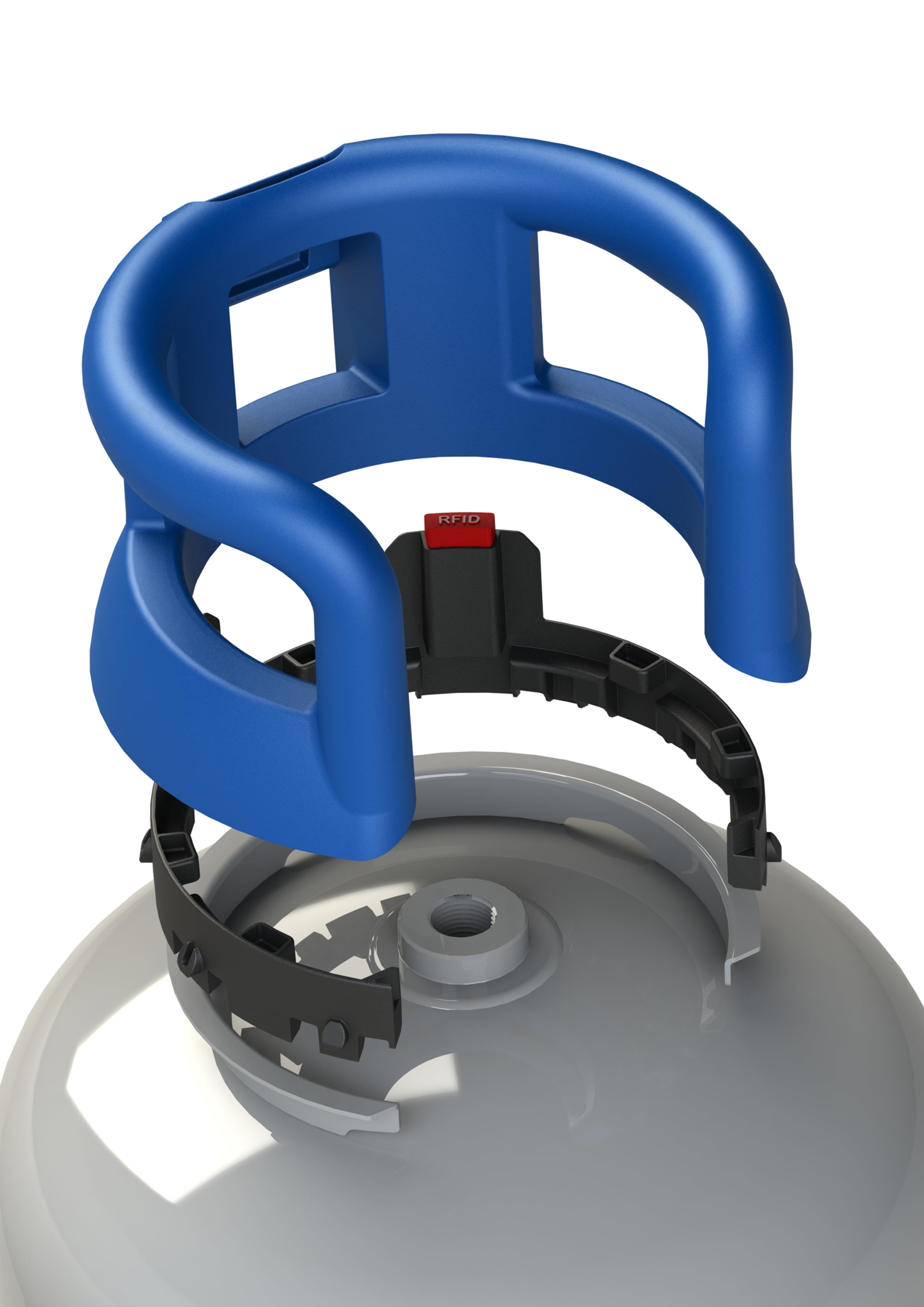

As an innovative solution for gas cylinders, ComfortCarry™ offers increased portability and improved ergonomics for older users. The fully recyclable, corrosion-free polymeric handle is designed to be easily diassembled, allowing better valve protection and longer cylinder life. Developed in Portugal, the RFID control also supports sustainable fleet management.