Cape Lambert Dolphin Upgrade

-

2022

-

Product

Commercial and Industrial

Designed By:

Commissioned By:

Designed In:

Australia

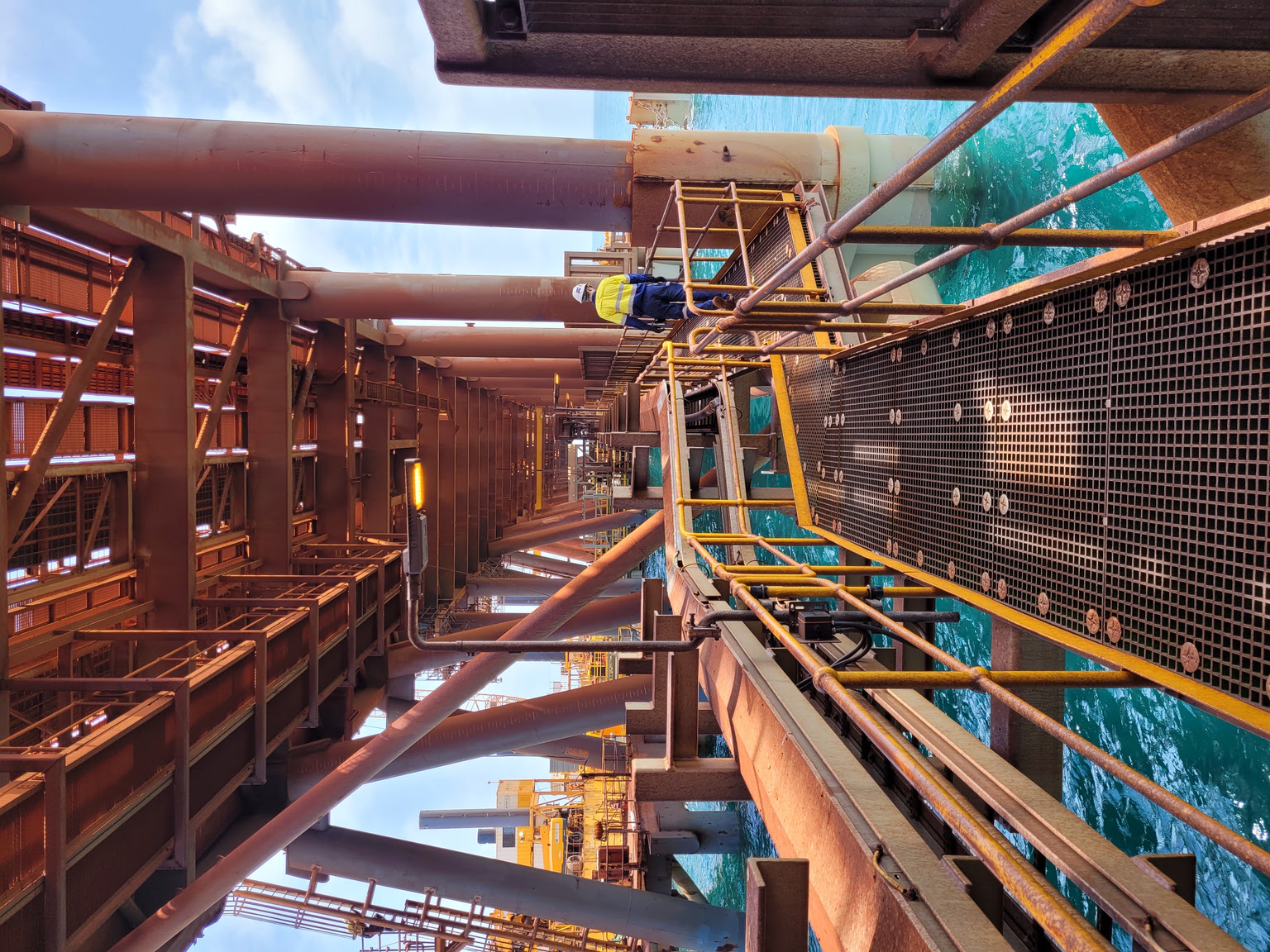

Cape Lambert is a major port facility operated by Rio Tinto in WA. The “dolphins” are critical infrastructure elements used to berth and safely moor vessels. Considering existing site conditions, design of the replacement dolphins and interconnecting walkways was based on 3D digital surveys achieving implementation within budget and schedule.