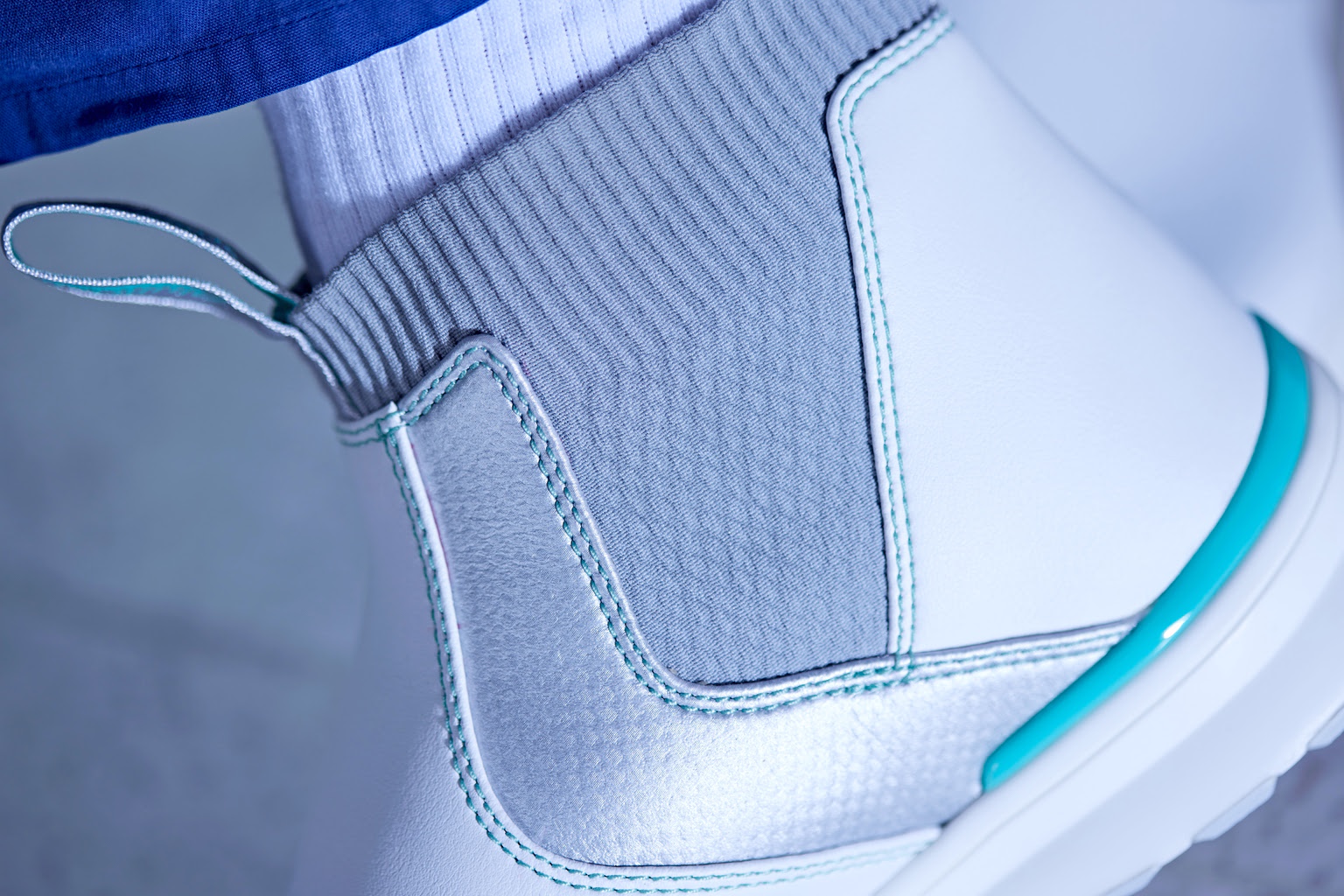

Blundstone Intelligent Footwear for Healthcare

-

2022

-

Design Research

Designed By:

Healthcare workers face some of the most demanding workplace environments leading to discomfort, musculoskeletal injury, and fatigue. This project brings together Blundstone’s rich history in workplace safety with Monash University’s research into cutting-edge fabrication, sensor technologies, and user-centred design to develop an intelligent shoe that provides real-time OH&S insights.