iVolve’s LX1

-

2025

-

Product

Commercial and Industrial

Designed By:

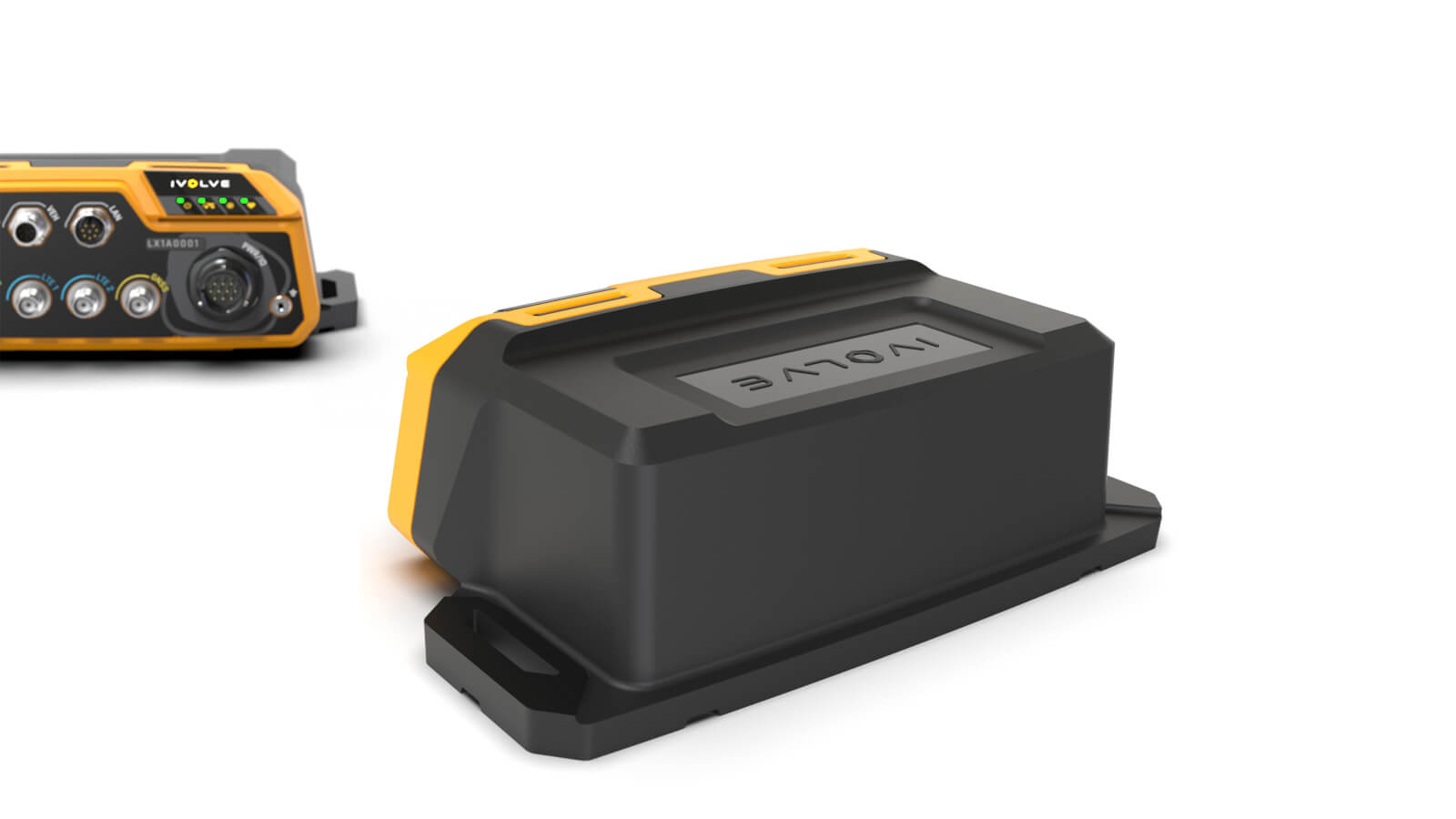

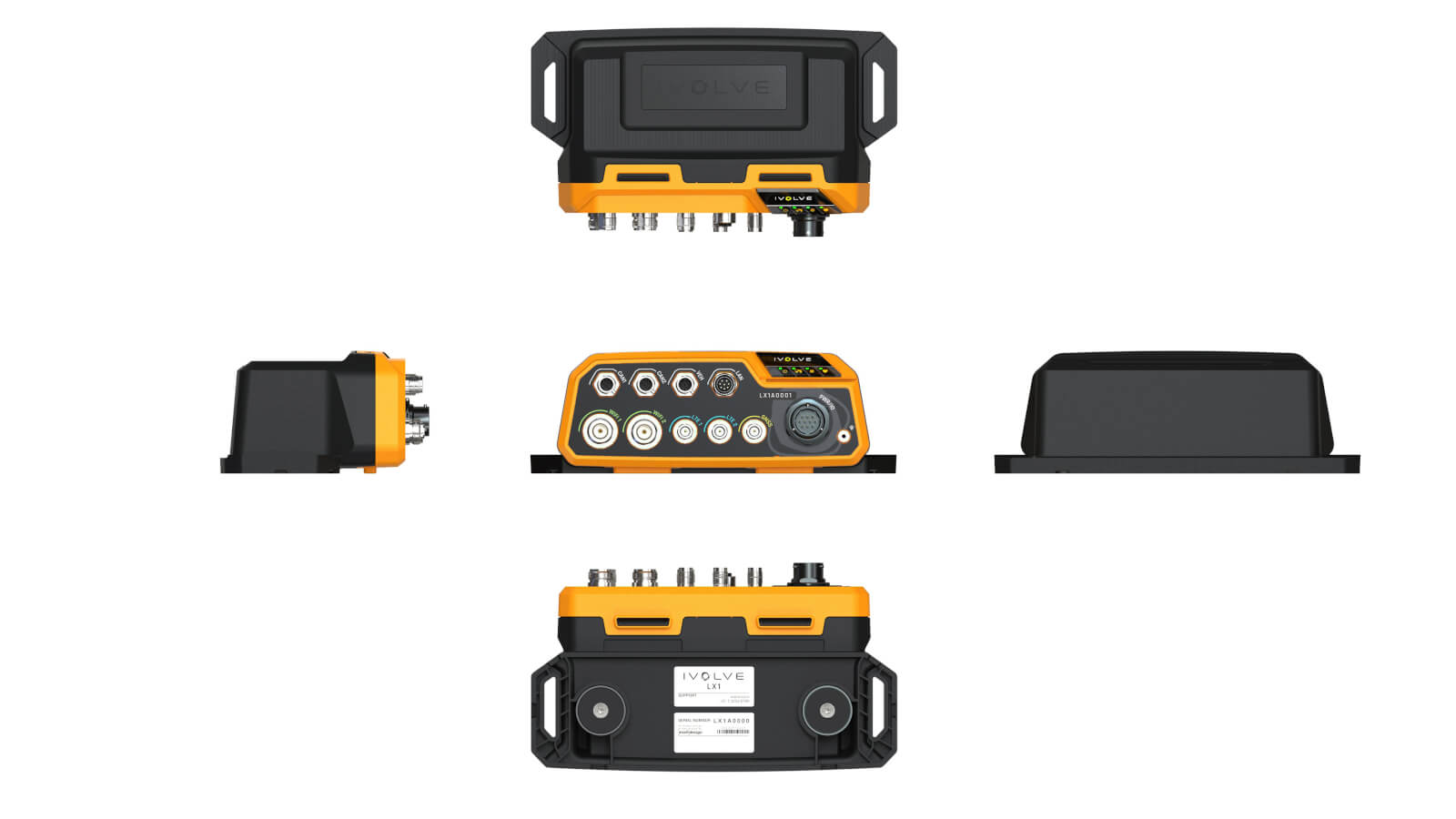

iVolve’s LX1 is an industrial brain designed for heavy machinery installation in Agriculture, Mining & Construction. The LX1 is designed for high-volume machine data processing & broad machine interface capability. Built upon iVolve’s previous generation Nexis system, the LX1 combines industry-leading machine interface catalogue with support for the latest generation of machinery.